Microturbines vs. Reciprocating Engines: A Deep Dive into Power Generation Technologies

In the world of power generation, technological advancements are shaping the way we produce electricity for our homes, businesses, and industries. One such innovation is the microturbine, a compact and efficient system that has proven to be an effective and environmentally beneficial approach to generating power. In this newsletter, we'll take a closer look at microturbines compared to traditional reciprocating engines and demonstrate that the former offers a number of advantages that could make a big difference when choosing a power generation source.

Though microturbines have been employed since the 1990s, they are comparatively new players in the power generation arena. These systems are miniature gas turbines and apply advanced engineering and design principles to create electricity.

Low Emissions: A Clean Advantage

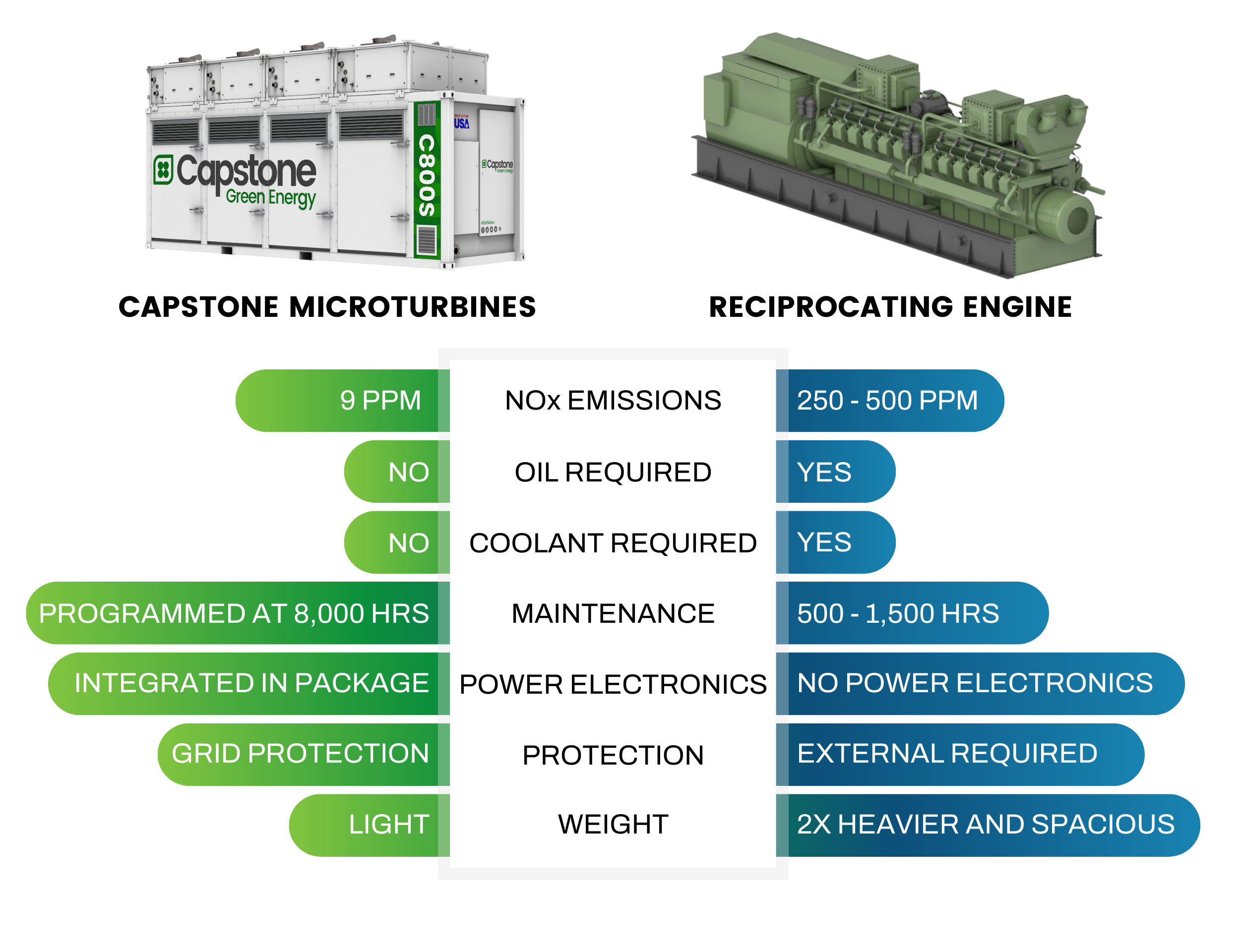

One of the most significant advantages of microturbines is their lower emissions production compared to reciprocating engines. Microturbines utilize a lean and well-mixed continuous combustion process, allowing them to maintain low emissions over a wide range of operating conditions. This allows the microturbine to operate in most regions without the need to purchase and maintain exhaust cleaning technologies. By contrast, reciprocating engines utilize intermittent combustion, whereby the fuel and air are rapidly mixed and ignited in a highly transient process that repeats hundreds of times each minute. This makes it more challenging to achieve uniform combustion, resulting in emissions that often require post-engine exhaust cleaning to satisfy local regulatory requirements. Though the technology has seen improvements in emissions reduction over the past decade, it continues to require additional treatments to achieve microturbine emissions levels. The primary benefit for Capstone is that microturbine customers don’t need to purchase, install, and maintain this equipment to remain compliant with local regulations.

Efficiency Matters: Heat Recovery and More

When it comes to overall efficiency, both microturbines and reciprocating engines have their strengths. Between the two, microturbines have an edge in handling heat recovery, an aspect that helps compensate for their lower electrical efficiencies. Most of the useable waste energy produced by microturbines is in a single high-volume, clean exhaust stream. Reciprocating engine generator sets reject roughly the equivalent waste heat but in two main systems: cooling jacket water and the engine exhaust. This makes heat recovery more complicated and places some limitations on the temperatures and types of heat recovery that can be accomplished.

Direct exhaust applications are also not optimal for reciprocating engines since only half of their useable waste heat is in the exhaust, and that exhaust can be contaminated with oil as the engine wears over time. Microturbine exhaust is oil-free, as is the single waste heat recovery stream, so it is possible to effectively use this heat directly in a manufacturing process or in a double effect absorption chiller.

Microturbines also feature a cooling mechanism. While reciprocating engines require water cooling for their engine jackets, microturbines primarily rely on air cooling, which reduces space requirements and dramatically simplifies installations.

Maintenance Made Simple

Capstone microturbines offer a distinct advantage when it comes to maintenance. The microturbines boast an innovative design with just one moving part coupled with advanced air bearing technology. This combination enables the microturbine to operate on a cushion of air, eliminating the need for oil or other lubricants -- which means no oil changes. As such, microturbines require less maintenance and have longer operating intervals than traditional engines. This not only leads to cost savings but also ensures reliable performance over extended periods.

Comparatively, reciprocating engines need oil to control wear on the sliding piston surfaces. This leads to thermal degradation and metal deposit buildup in the lubricant as well as the need to dispose of used oil. While large storage tanks of oil can be used to extend service intervals, natural gas-fired reciprocating engines also need periodic valve adjustments and spark plug replacement.

All that can add up in significant cost and effort over time. A typical maintenance schedule for a small natural gas-fired reciprocating generator set is roughly every 1,000 operating hours. Whereas microturbines only typically require a filter check at 4,000 operating hours and a filter replacement at 8,000 hours.

Compact, Lightweight, and Low Vibration

The compact and lightweight nature of microturbines is a significant departure from bulkier reciprocating engines. This characteristic makes them easier to install and integrate into various spaces. Moreover, microturbines generate less vibration, which provides a smoother, less disruptive experience both operationally and structurally.

Technology for Tomorrow: Control and Interconnection

Microturbines incorporate innovative inverter technology, which not only converts the high-frequency turbogenerator output into usable power, but it also adds intelligent control features. This technology enables functions such as protective relaying, synchronizing, and load sharing, making microturbines adaptable to various grid and utility interconnection requirements. Microturbines are even certified to multiple interconnection standards, a factor which helps streamline the integration process.

Making the Right Choice: Tailoring Power Generation

Ultimately, the choice between microturbines and reciprocating engines hinges on a site or application’s specific needs. Factors such as emissions control, maintenance intervals, and overall efficiency play a pivotal role in the decision-making process. Careful analysis and understanding of these factors are crucial for selecting the technology that best aligns with your power generation goals.

As the landscape of power generation continues to evolve, microturbines stand out as a compelling, efficient, and often more cost effective option. Their clean combustion, versatility, and low maintenance requirements position them as leaders in sustainable energy solutions.

Stay tuned for more updates on cutting-edge technologies that are reshaping our world and paving the way toward a greener future!